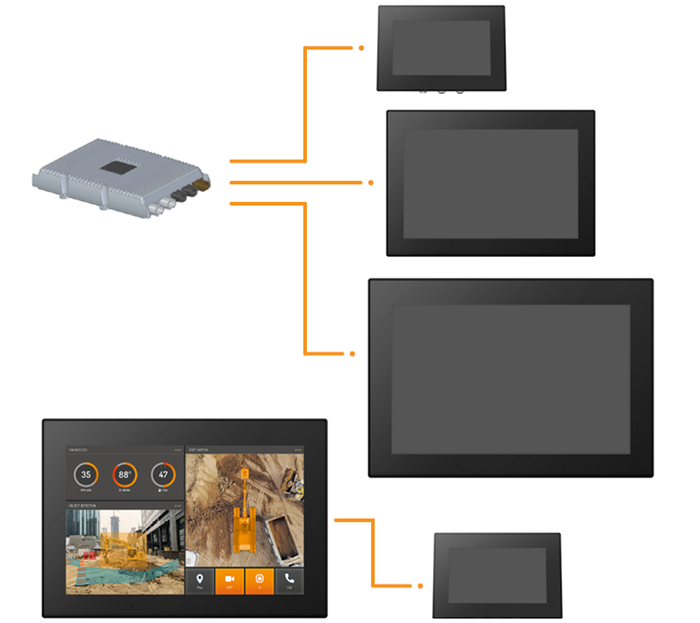

Display ECU with multiple monitors

Our new product concept for an HMI system features a central display ECU which drives multiple monitors. Modern vehicles are increasingly equipped with more productivity tools like process control, guidance, and ADAS as well as diagnostic and system tools for machine health.

We are already seeing, for example in agricultural tractors or road graders, that cabs are fitted with multiple HMI displays to support these various systems.

With our new concept, display applications for the various systems run on a common, central Display ECU that drives several monitors. This enables moving applications between the physical screens and thereby adapting the HMI system to fit the interaction needs for various work modes and tasks. And it would enable operators to customize and personalize the interaction to fit their preferences.

In our demonstration unit we use two display monitors - one 12"" and one 7"". The monitors are driven by a common display ECU over an FPDLink interfaces. The display ECU uses an iMX8X quad core application processor with a very capable, Vivante GC7000lite, graphics processing unit that manages to easily render several, graphically advanced applications simultaneously.

As part of the CC Linux OS we have implemented the CrossControl framework for moving applications dynamically between the physical screens. And as you can see in the accompanying video, the window management solution allows users to change the look of an application to adapt to available screen real estate and the task at hand.

In the demo system shown in the video below, there is an ISOBUS UT application, an instrumentation application, and a guidance application. In this example the user can enable transportation mode, with the instrumentation app in the dashboard and when in the field, they might want to have the guidance app front and centre, or in full screen mode in the side display. The Universal Terminal might run in half screen mode in the side display in the normal state. But the user can also pull it up to full screen to manage his implement settings.

The split concept ECU driving multiple displays provides flexibility to system designers and end users, separates TFT and computing technology, and provides the hardware needed to address the new changes in system design and deployment to empower machines to be smarter, safer, and more productive.

Easy realization thanks to versatile technology platform

The technology platform behind this display ECU and monitor concept consists of modules and we have defined an architecture for how modules are integrated at both an interface and signal level. With this approach, modules can be developed and validated independently of each other. The platform is manifested in a set of module boards that can be combined to form functional prototypes. The advantage of early prototypes that can be rapidly assembled allows for simpler software development and a faster time to conclude the proof-of-concept phase of a project.

By pre-validating the module boards, both in terms of hardware design and software, lead time to realize a final product is shortened and risks are reduced both for commercial off-the shelf projects and custom designs for larger programs.

The different parts in the functional prototype board set-up for the Display ECU are a main board with the application processor, in this case an iMX8X quad core, a power supply board and a display interface board. Then we have additional boards for CAN, Ethernet, and other external interfaces. Finally, there is a slot for a mini PCIe board, which can be used for extending functionality for example an AI accelerator module can provide greater performance levels in machine-learning supported applications like object detection.

These board assemblies are just used for functional prototyping. After this stage of a project, we take the module schematics and merge them into a single board design for our released products like the CCpilot V700 or a custom creation for larger programs.