Upgraded Modular ISOBUS Terminal Platform

News

Instant UI on a Linux based system

2025-06-27

News

First integrated network switch in a display

2025-06-27

News

Robust update with CC Linux 4

2025-06-27

News

Versatile small format displays – CCpilot V510, V705, and V710

2025-03-04

News

Modules and resources for vehicle communication solutions

2025-02-25

News

Integrate applications into HMI systems to add functionality

2025-02-25

Event

Meet us at Bauma 2025

2024-12-11

News

Prepare for new cyber security requirements

2024-11-19

News

New display computers for precision applications, 2D/3D machine control and ISOBUS

2024-11-18

News

Optimised Start, Boots made for walking (and running)

2024-11-09

News

Meet coming cyber security regulations

2024-11-08

Event

CrossControl to showcase next generation HMI & computing solutions in Germany

2024-04-25

Event

CrossControl showcases next generation HMI & computing solutions

2024-04-25

News

Next generation on-board computing platform

2024-04-03

News

New integrated display computers for precision systems

2024-03-25

News

Vehicle Computer & Monitors – New product line

2024-03-21

News

Birds eye view vision system

2023-12-12

News

New 5” and 7” displays

2023-12-12

News

CrossControl at Agritechnica

2023-11-30

News

Versatile terminal platform - for ISOBUS & precision systems

2023-10-17

News

Introducing the new CCpilot V510 and V710

2023-10-13

News

Core technology platform for onboard computing and HMI display products

2023-10-13

Event

CrossControl showcase at Teknologia 2023

2023-10-12

News

LIDAR, Cameras, Action!

2023-07-12

News

Visit us at IVT Expo in Chicago

2023-07-11

News

New iMX8 displays with softkeys

2023-07-11

News

New extreme line display computer

2023-07-11

News

Showcasing the current and next generation of HMI platforms

2023-06-12

News

Applied AI

2023-06-12

News

Independent application management

2023-06-12

News

Computer Vision - Virtual Fencing and Object Detection

2023-04-27

News

Electrified Tundra Buggy

2023-03-20

News

CrossControl in 60 seconds

2023-03-20

News

On Show in Vegas

2023-03-20

Event

iVT Expo Cologne 2023

2023-03-20

Event

iVT Expo Chicago 2023

2023-03-20

Event

Visit us at Agritechnica 2023

2023-03-20

News

Engineering week

2023-02-21

News

CrossControl on display in Vegas

2023-02-10

News

Vision system

2023-02-10

News

Start me up! Boot in 3 sec

2023-02-10

News

PC based display computers

2023-01-20

News

Award winning platform

2022-12-07

News

Our latest CC Linux

2022-12-07

News

Modular technology platform

2022-10-04

News

CrossControl’s first line of support

2022-10-03

News

Software is transforming the capabilities of industrial vehicles

2022-08-25

News

Adapt to industry trends with a modular technology platform

2022-08-25

News

iMX8-based displays from 7”-12”

2022-08-25

Event

CrossControl will be at ConExpo 2023

2022-08-09

News

iVT Expo Chicago 2022

2022-07-04

Event

iVT Expo Chicago 2022

2022-07-04

News

Join us in exploring the latest technology at iVT Expo in 22 in Cologne and Chicago

2022-06-03

News

Modular software platform adds new features

2022-06-03

Event

iVT Expo Cologne 2022

2022-04-13

News

Visit us at the Teknologia show

2022-04-04

Event

Come and visit us at Teknologia’22

2022-03-07

News

Spring 2022 product showcase

2022-03-02

Event

Spring 2022 Product Showcase

2022-03-02

News

Technical skills led to an engineering career

2022-02-24

News

Watch our latest video showcasing iMX8 based display computers

2022-02-08

News

Object detection made lean

2021-12-23

News

Take a look at our new iMX8-based display computers

2021-10-22

News

New iMX8-based display computers in sizes 7’’, 10’’ & 12’’

2021-09-06

News

CCpilot V700 – Next Generation of HMI Computing Technology

2021-07-10

News

Combine the best of CODESYS and Qt

2021-05-18

News

Human Factors in the Development Process of Immersive Visual Technologies

2021-03-23

News

CrossControl supports HTML5

2021-03-18

News

Dr Markus Wallmyr at iVT Virtual Expo 2021

2021-02-22

News

CCpilot V700 is designed and tested to meet the most demanding requirements

2021-02-10

News

Richard Hedlund wins Lilla Polhemspriset

2020-10-27

News

Smart Industrial Machines See the Future Like Never Before

2020-10-12

News

Fast Boot Time - What can you do in 4 seconds?

2020-09-21

News

CrossControl Launches the CCpilot V700

2020-09-10

News

CCpilot V700 – Under the Hood

2020-09-10

News

Support for Dynamic Multi-Touch

2020-06-15

News

How HMI display solutions can impact operator productivity in industrial vehicles

2020-04-02

News

Using modern trends to study operators in remote locations

2020-03-04

News

Rapid increase in software requirements means new platform development

2020-03-03

News

Learn More About iMX8 based product development and testing at ConExpo 2020

2020-02-25

News

Upgraded Modular ISOBUS Terminal Platform

2020-01-10

News

A software platform built with the future in mind

2019-11-27

News

Machine Intelligence Platform on show in Hannover

2019-10-28

News

Join us in Helsinki to discuss the future of HMI solutions

2019-10-28

News

On Machine Operator Guidance

2019-09-06

News

Soft Telematics Solutions

2019-08-26

News

New 9” High Performance Display Computer

2019-08-20

News

Join our System Design Webinar, on the 9th of May

2019-05-02

News

Operational excellence

2019-04-30

News

The crowds turned up for Bauma 2019

2019-04-17

News

Versatile Telematics Platform

2019-04-05

News

Getting really connected

2019-04-02

News

Expanding to Infinity

2019-03-25

News

New display and telematics products at Bauma, hall A2, stand 326

2019-03-19

News

Introducing the new CCpilot VI 3.5"

2019-01-16

News

Augmented Reality and Communication at ILA18

2018-12-03

News

Smart and Lean Telematics

2018-11-28

News

CrossControl at Bauma China

2018-11-21

News

CrossControl at MaatalousKonemessut tradeshow

2018-11-12

News

CrossControl at Elmia tradeshow

2018-11-09

News

Meet CrossControl at the Utnarm career fair on November 8th

2018-11-07

News

Launching a new 3’’5 display

2018-10-26

News

Safety at any cost – without cost

2018-10-09

News

Technology demo: Soft FM/DAB radio in CCpilot display

2018-08-07

News

IP video support in CCpilot displays

2018-05-02

News

CrossControl at Intermat, booth 5A C160

2018-04-25

News

Application story - The new CCI-1200 ISOBUS terminal

2018-01-15

News

Government and Municipality representatives visit production plant

2017-11-01

News

Explore our NEW multifunctional ISOBUS terminals at Agritechnica!

2017-10-06

News

NEW sunlight readable 12" display

2017-10-02

News

Meet us at Teknologia’17 in Helsinki Oct 10-12!

2017-09-20

News

PhD student in Computer Science

2017-09-19

News

Conference on future HMI-solutions

2017-08-30

News

Take a peek at our production plant

2017-06-29

News

Meet U-CONTROL at SPS IPC Drives in Italy

2017-05-22

News

Easy design of premium GUIs

2017-04-12

News

Planned Life Cycle Management is a necessity

2017-03-17

News

Learn more about global trends in machine control

2017-02-06

News

New family of I/O control products

2017-01-16

News

New release: CrossLink AI wireless module

2015-12-10

News

New release: Smart connect – Apps out of the box

2015-12-08

News

Starter kits – all included

2015-11-30

News

Thank you for meeting us at Agritechnica!

2015-11-13

News

Controller with CANopen and J1939 support

2015-10-15

News

Next generation display computers

2015-06-15

News

Handling advanced graphical features

2015-05-21

News

CCpilot VA, a new 7” display computer

2015-04-07

News

Next generation CCpilot XM

2015-02-04

News

The Latest Research into the Future of HMI Solutions

News

CrossControl is launching NEW ISOBUS terminals

News

Continuous improvements for World-Class Operations

Event

Bauma 2022

News

Upgraded Modular ISOBUS Terminal Platform

2020-01-10

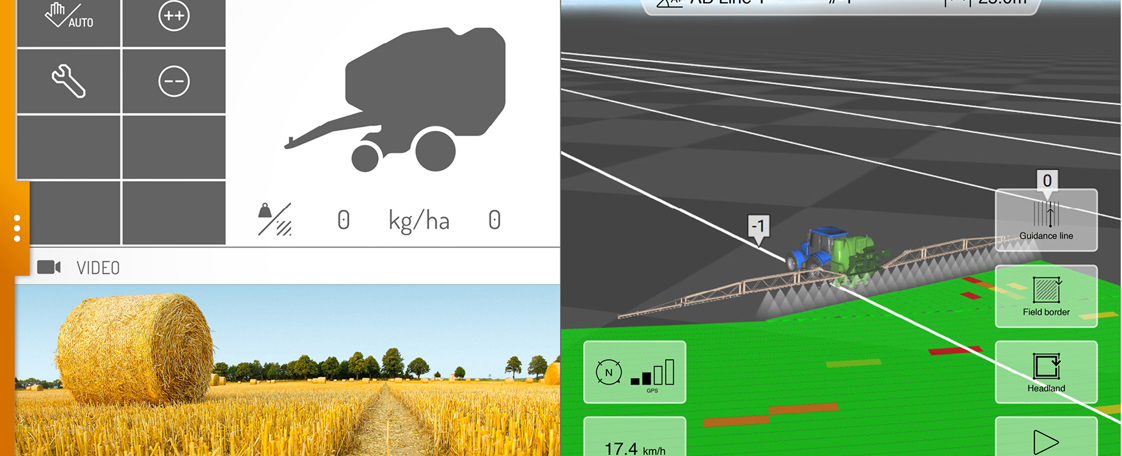

As part of our wide portfolio of products CrossControl recently unveiled significant updates to our multi-functional ISOBUS Terminal Platform.

The changes include a new state-of-the-art 7” display featuring the latest ARM processors and a premium 12” display with a bright high contrast display for true sunlight readability. The 7” & 12” displays come with high resolution, PCAP touch screens. The 12” display has the power and screen real-estate to run several applications in a windowed arrangement. As an example, it is possible to simultaneously display a UT, guidance application, video monitoring and machine instrumentation in one array. This flexibility, combined with the open nature of our software allows adopters of the platform to create a unique and value adding solution for their machine without the restrictions that come with other ISOBUS terminals. The next generation of 7” displays is designed to satisfy more compact ISOBUS terminal needs, but retain multi-functional capabilities. With the smaller screen real-estate the system can be set-up so that the user can navigate between different applications with simple touch controls or through input from a connected controller, such as an armrest panel or joystick. This allows intuitive navigation between screens.

The displays run the latest version of our ISOBUS software package. Our version of the Universal Terminal provides a rich ISOBUS experience, with the ability to customize the look-and-feel of the UT to reflect both the OEMs brand and graphical style and the interface that provides the best user experience for that equipment.

CrossControl Displays feature an open Linux OS and support Qt for premium visual applications and cross platform support. On top of this base layer, CrossControl deploys the LinX Software Suite, an open and modular development tool chain that helps OEMs and System Integrators reduce engineering spend and shorten time to market. By using the LinX Software Suite to deploy our version of ISOBUS, CrossControl is able to run the UT and non-ISOBUS features like video monitoring and machine diagnostics concurrently, displayed side by side on larger displays like the 12” CCpilot VS and in switchable windowed applications on the smaller 7” displays. This creates a truly multifunctional ISOBUS terminal capable of handling all HMI needs in the cab. The latest version also includes the ability to run two UT applications concurrently for controlling multiple implements at the same time, increasing user efficiency and flexibility. Our new GeoSuite package for the LinX Software Suite combines the Task Controller that is integral to the success of modern ISOBUS systems and a new advanced navigation and guidance application. The TC functionality includes both simple data collection and geo referenced data storage. This allows users to precisely map yield production down to the smallest area, monitor crop patterns, adjust to trends and fix problems; quickly and precisely. In addition to yield mapping, geo-referenced data logging can also be used for tracking actual application rates for spray, fertilizer, and seed, or for soil sampling. The package includes an advanced navigation and guidance add-on application which provides additional operator aids. The application can incorporate direct GPS data, prebuilt maps from the farm or third party guidance support into a 3D field display. Complete with implement graphics and control tools. Field data and position are customisable by the user through the intuitive touch interface, so the user can adjust imported section control and operating guidance tools to suit their needs. The feature includes common and customisable guidance patterns and the interface and control functions needed for automatic steering. The mapping and autonomous drive system ensures the vehicle stays on the optimal path freeing up the operator to concentrate on other important tasks. By providing customers with a modular platform it is possible to create a tailored solution that suits any iron, whatever the colour.